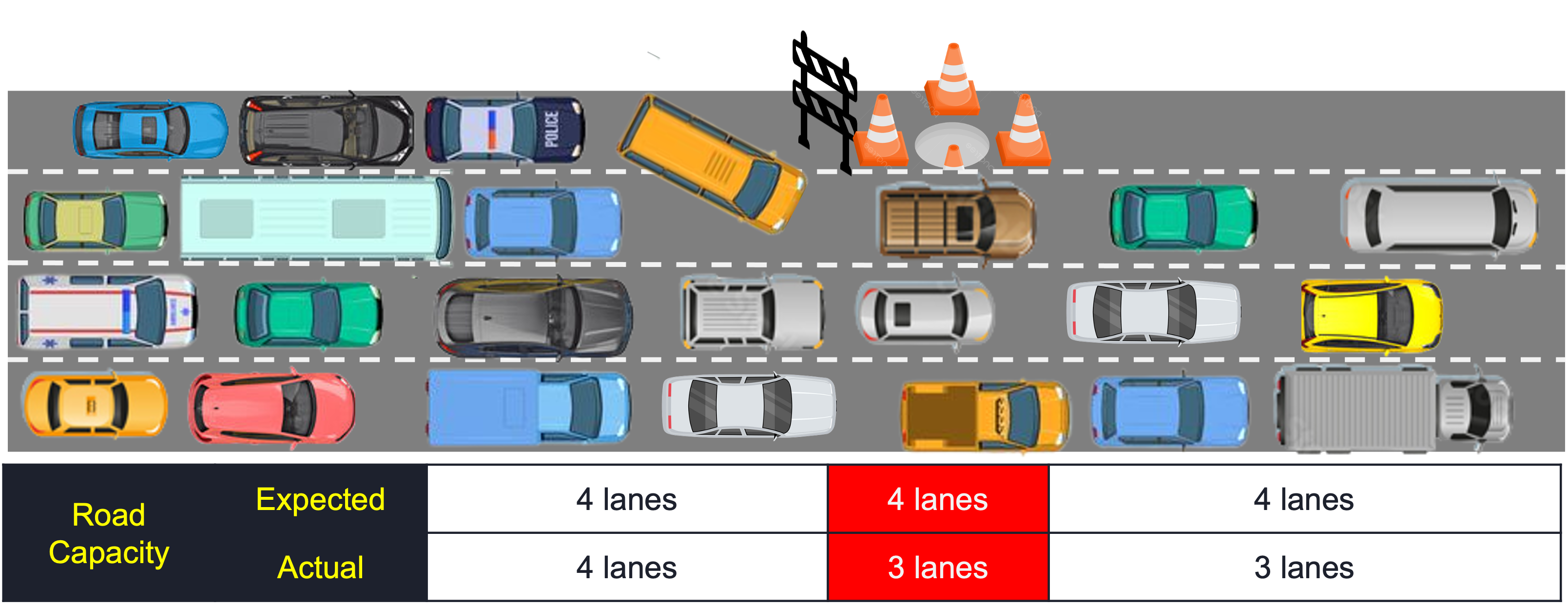

What is a Bottleneck?

Bottleneck A process step that becomes a congestion point or a blockage for flow of work. It is like the neck of the bottle - smaller (in diameter) - that restricts the flow of contents from the bottle. In Lean manufacturing, the process step that is having highest cycle time in a value chain is considered as bottleneck. Theoretically, any process steps having the lowest capacity are called bottleneck processes. The strength of the chain is as high as the...