Efficient Production Management

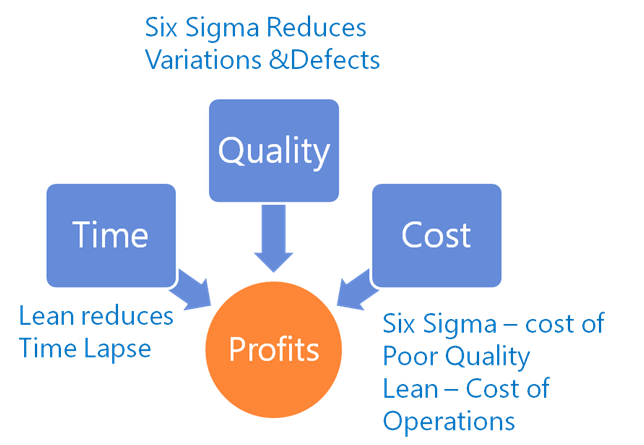

Refresh your memory and learn something new from CSense LSS Yellow Belt Training. I am planning to conduct a series of courses completely free for everyone. To start with, we will work on the Lean Six Sigma Yellow Belt program. What is Lean Six Sigma? Lean Six Sigma is the most effective methodology used across the world by companies of all sectors. It is providing millions and millions of dollars as cost-saving and a multi-fold increase in business growth. Who...

ONLINE CERTIFICATION TRAINING Learn from the Experts! Minitab Batch: July 31 & Aug 1 - 6 pm to 9.30 pm Excel Batch: Aug 1 & 2 - 9.30 am 1.00 pm Basics of Data Analysis This program covers the basics of Data Analysis. Don't worry about your current proficiency. Green Belt Tools It will help you perform all the statistical analysis required for a Six Sigma Green Belt Project. Minitab / Excel Choose between Minitab or MS Excel - Two...

Advanced Problem Solving Methodologies - Design of Experiments - DoE It was a hot summer and I was travelling through the deserts of Western India. A wonderful piece of land with varying lifestyles every few hours of drive. I eagerly looked at the domesticated camels and started thinking about how things happened so quickly and how did I manage to plan my trip to that well-known cement factory for a DoE engagement. A week before – I received a call...

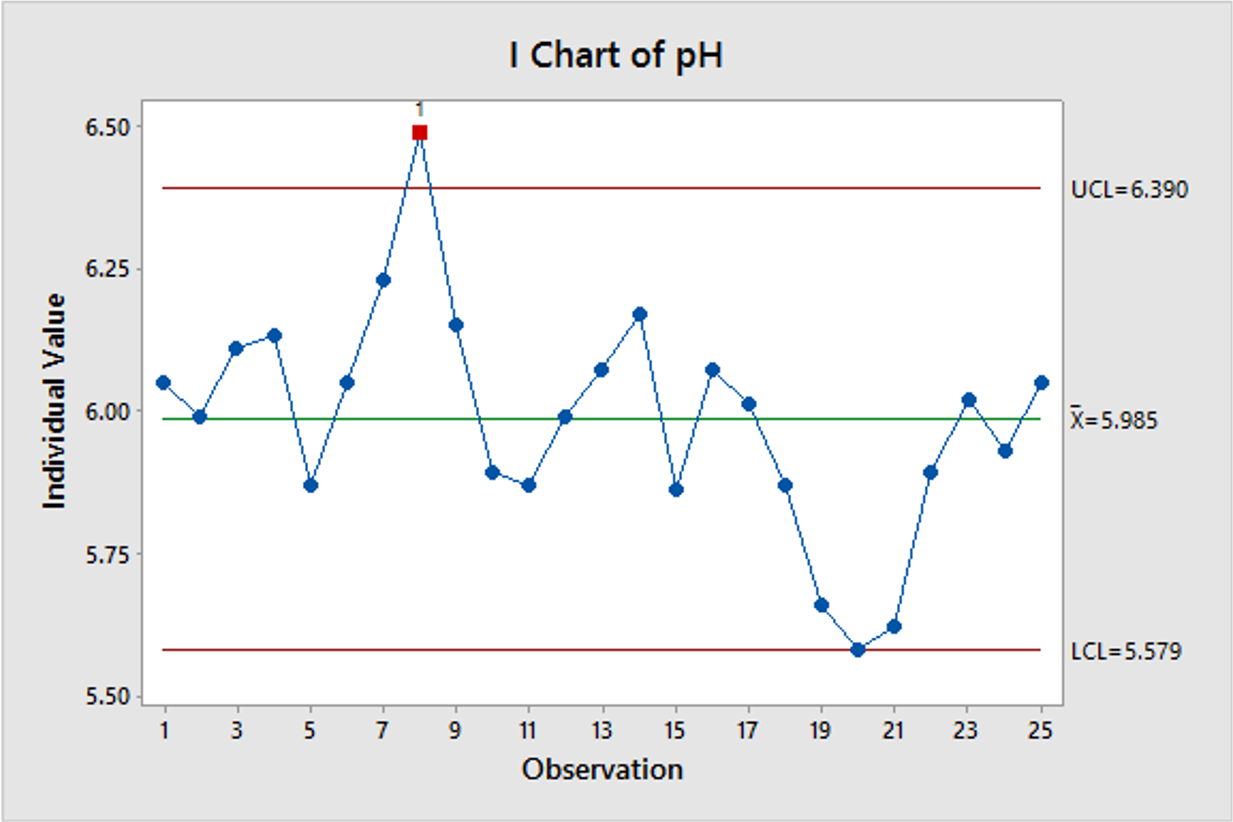

Another fantastic two-days for me! I delivered a 2-day program on Achieving Zero Defects using Statistical Process Control (SPC) at CII Centre of Excellence, Mumbai, last week. Managers from renowned manufacturing companies like L&T, Hawkins, Owens Corning, Galaxy Surfactants and more have participated enthusiastically. Discussed cases of Western Electrical, Motorola and Japanese Automobile Companies. Interesting to see that SPC is underlying thread in the success of American companies, and equally of Japanese companies. We discussed how did those companies utilise...

What is 8D Problem Solving? 8D problems solving is one of the basic and effective problem-solving tools. Here, the Ds refer to 8 disciplines - the 8 steps of managing a problem and preventing its recurrence. 8 Steps of Problem Solving History During the 1980s, the Ford Motors was under the crisis - unable to cope up with the competition from the Japanese automobile companies. They requested Dr. Deming to support them to bring the company back to its effective...

Design Of Experiments (DoE) Training using Minitab The Design of Experiments (DoE) is a statistical way of establishing the mathematical relationship between outcome and factors affecting the outcome. It helps us in arriving at a minimum required trials and sequence of conducting those trials – considering bias and disturbances of conditions, establishing the relationship with mathematical accuracy. With this two-day program, participants learn about basics statistics for decision making, constructing unbiased and failure-proof experimental design, Analyse response and optimise parameters...

Statistics for Big Data & Analytics CSense Statistics for Big Data & Analytics is designed for experts venturing into Data Science - Big Data and Data Analytics, helping them to have a strong foundation with statistics. Data scientists say that every second we are creating close to 1 megabyte of data per capita, and the volume of data is growing than ever before. In line with the availability of data, studies on collecting the data, processing them, analysing and interpreting...

Minitab Training will help you understand statistics and data analysis and give you hands-on Minitab Software. This program covers basic statisitical theories and tools along with Minitab tools and application. The Minitab Data Analysis program is structured on Six Sigma's DMAIC framework. What is Minitab? Minitab is a software package that helps us in the analysis of data. It is also extensively used by Six Sigma Experts a is an important part of studying data, particularly in the Measure and Analyse...

Lean Six Sigma Green Belt Training and Certification What is Lean Six Sigma? One of the most Powerful business transformation tools used all over the world across every industrial sector for past tow decades. It is becoming a must-be in many companies in developed countries and in MNCs in India, gaining momentum among many Indian corporate houses in the past decade. Automobile, Electronics, and Banking have already ventured into LSS – improving the quality of our lives and Telecom, medicine, engineering, BPO and...