வார்த்தைகளைத் தாண்டிப் புரிந்துகொள்வோம் – தரம்

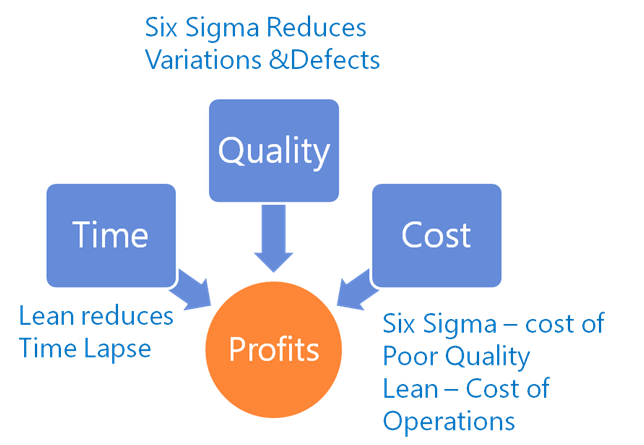

வார்த்தைகளும் வழக்கு மொழிகளும் பல நேரங்களில் நம் கண்ணை மறைத்துவிடுகின்றன. அந்த விதத்தில் நாம் இன்னும் சரியாகப் புரிந்துகொள்ளாத ஒரு வார்த்தை - Quality. Quality என்றால் என்ன? தரம் - இதனை குறையற்ற தன்மை என்றும், குறிப்பிட்ட பயன்பாட்டிற்கான தகுதி என்றும் கூறலாம். Quality குறித்த பல வரையறைகளுள் குறிப்பிடத் தகுந்த சில – American Society for Quality – ASQ தரத்தைப் பின்வருமாறு வரையறுக்கிறது. Quality என்பது ஓர் அனுபவம். அறிவியல் பூர்வமாகப் பார்க்கும் போது அதற்கு இரண்டு அர்த்தங்கள் கொள்ளலாம். குறிப்பிட்ட அல்லது எதிர்பார்க்கப்படும் தேவையைப் பூர்த்திசெய்யும் திறன் மற்றும் குறையற்ற தன்மை. தரவியலின் தந்தையாகப் போற்றப்படும் அமெரிக்காவின் எட்வர்ட் டெமிங் தரத்தைப் பின்வருமாறு வரையறுக்கிறார் – பயன்படுத்துவோரின் தேவைக்கு ஏற்றதுபோல் பொருளை...