What is Takt Time?

Takt time is the time given by the client to the manufacturer to pull out one piece of finished material from the plant.

In other words, it is the time (frequency) at which the manufacturing plant to complete one unit of its product.

We can also describe it as the demanded exit rate of a plant.

How to Calculate Takt time?

Calculate monthly average demand for the product/product family (we can calculate takt time for a product or a product family).

Calculate the Available working hours (planned working hours – downtime, change over time and other time losses). It is recommended to keep the time in seconds, if not in minutes.

It is the Time given per piece. So, divide the available time in a month by the demand for the month.

What it Takt?

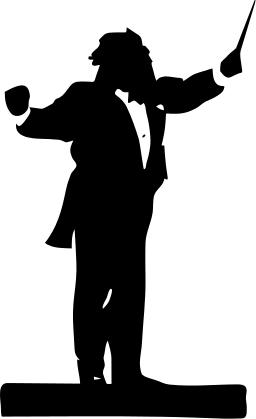

Takt is a German word meaning the ‘Orchestra Conductor’s Wand’. The speed of the wand alters the rhythm and tempo of the orchestra. Similarly, in an orchestrated manufacturing process (Lean or flow production), this ‘Takt Time’ determines the speed at which the processes have to complete one component.

Here, the production manager adjusts resources to match the output of each of the process to match this time demand.

Note: It is different from Lead Time.