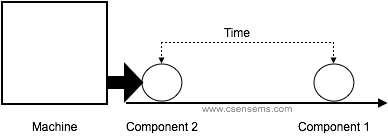

Cash to Cash Cycle Time

What is Cash to Cash Cycle? Cash to cash cycle time is the time lapse between payment to suppliers and getting payment from the customers. Every business exists to provide a tangible or intangible product to the people in need and make money out of those provisions in the form of profit. A company has to invest money in the business. There are 2 types of investments - Asset Capital and Working Capital. When a company spends money on creating...