Lean Training with Value Stream Mapping (VSM)

Lean Training with VSM is designed for people who are interested in learning the Lean Transformation using VSM. Value Stream Mapping – the mapping of Material and Information Flow – as it is known in Toyota is the fundamental tool of Lean Transformation. It helps us in mapping flow of information and material in a single process map.

Lean is a strategic tool that has to be adapted and applied by the Top Management. With Value Stream Mapping, we document, analyze every step of the current process and design a future state in line with the expectations of the customer and the business leading to Lean Transformation.

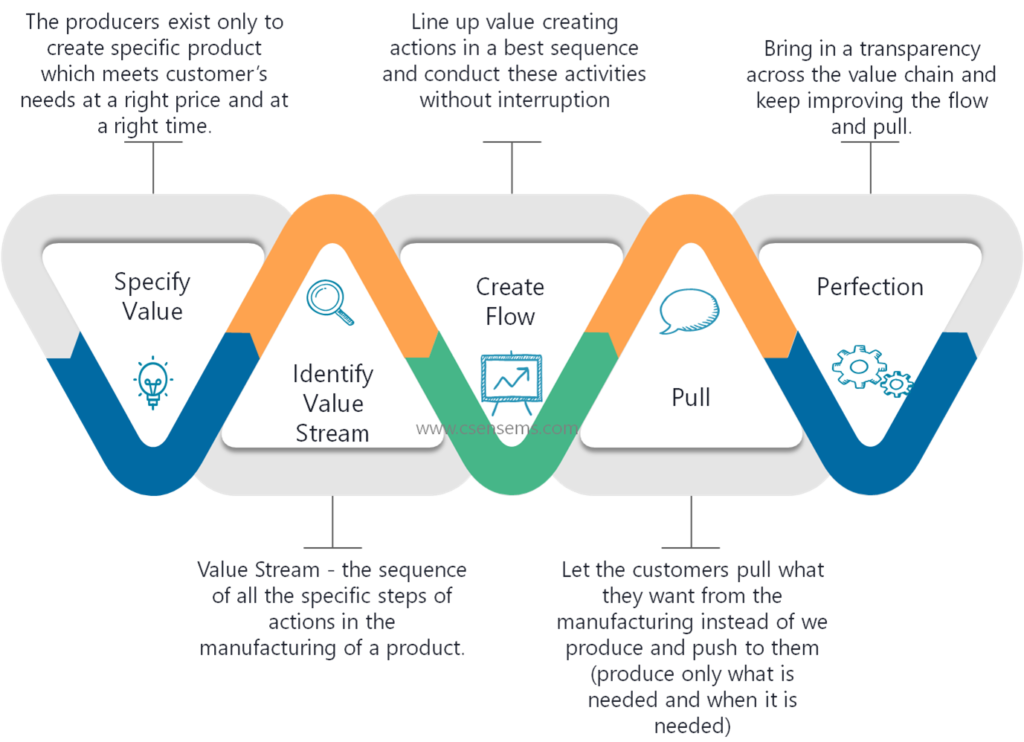

We discuss the Philosophy, Principles, and Practices of Lean in this Lean Training Program. The Principles cover value, value stream, identifying value streams, choosing the right value chain for Lean transformation. Along with these, we will also discuss the support mechanism of Lean transformation viz., SMED, Kaizen, Problem Solving, Andon, Poka-Yoke, TPM (Autonomous Maintenance and Planned Maintenance), and 5S.

Course Contents

Introduction to Lean

- Evolution of Lean

- What is Waste?

- What is Velocity? – Significance of Cash to Cash Cycle in Lean

- Lean Efficiency Metric – Process Cycle Efficiency

Value Stream Mapping (VSM)

- What is Value & Non-Value: in terms of business and in terms of customer

- Value Stream: how the value is created within the process flow

- Mapping Tools Complementing VSM – 4 levels of Process Flow Diagrams & Spaghetti Diagram

- Who has to own VSM Projects?

- What is Value Stream Management?

Terminologies

- Takt Time: The time provided by customer to produce one piece of product

- Process Time: The sum of cycle times in the value stream

- Throughput Time: total time a finished piece has taken from raw material through value stream

- Other Time measurements

- Material & Information Flow

- Timeline

- Calculation of Process Cycle Efficiency

As is or Current State Value Stream Map

8 Steps of mapping current state value stream

- Identify Product Family using Product Family Matrix & Business Potential Analysis

- Get customer demand and calculate takt time

- Map customer order requirements and despatches

- Map Order Processing, Purchasing from Suppliers and Receipt of Raw material

- Track movement of material across processes with cycle time and inventory counts

- Map the communications

- Draw timelines and calculate Process Cycle Efficiency

- Identify Bottlenecks

Overview of Future State Value Stream Map

Lean Optimisation Tools – Overview

- Set up time Reduction

- Overall Equipment Effectiveness (OEE) & Total Productive Maintenance (TPM)

- 5S – is it all about housekeeping?

- Poka Yoke – mistake proofing

- Workstation Design

Course Duration

2 days – 16 hours

Workshop Methodology

- Learning by Listening

- Learning by Teaching

- Discussions, Quiz & Videos

- Exercises

- Gemba Observation

- In-house case study (your own cases, examples, and Gemba observations)

Target Audience

- Managers, Executives and Shop floor supervisors involved in Process Improvement initiatives or Lean Transformation from Manufacturing, Engineering, and Auto companies

- Team Leaders, Project Managers and key people from IT and services company, looking for re-engineering the processes and improving efficiency

- Owners and Key People from SMEs looking for profit enhancement

- Key decision makers from any business interested in innovation and disruption

- Aspiring Students getting into industry