What is Problem-solving?

Before we understand problem-solving, let us first calibrate ourselves on ‘what is called a problem?’

A Problem

When there is a gap between our expectations and reality, we feel unhappy – which is a Problem. This is how a deviation from the specification, a failure to meet timelines, etc., become our problems. A problem could be defined as “the gap between our expectations and actual state or observation”.

From the gap analogy, we also understand that as the gap increases, our suffering intensifies.

Problem-solving

A fundamental part of every manager’s role is problem-solving. So, being a confident problem solver is really important to your success.

Much of that confidence comes from having a good process to use when approaching a problem. With one, you can solve problems quickly and effectively. Without one, your solutions may be ineffective, or you’ll get stuck and do nothing, sometimes with painful consequences.

Managing the problem (correction) instead of solving it (with corrective action) creates firefighting in our daily work. To solve a problem permanently, we need to understand and act on its root cause. We will also follow the steps of identifying root causes and prevent their recurrence in this workshop.

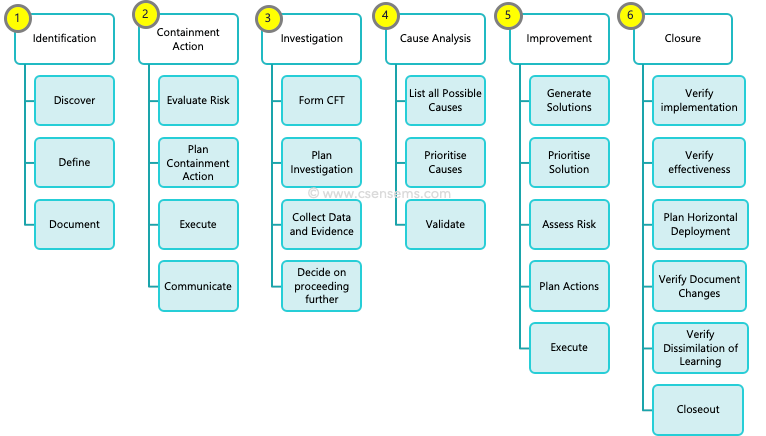

Systematic Problem-Solving

CSense IC3 Approach

- Identification

- Containment Action

- Investigation

- Cause Analysis

- Improvement

- Closure

Applications of methodology

The methodology is simple and applicable to most of the problems faced by the industries. Hence, it is widely accepted and recommended by companies. This also forms a framework for Auto industries’ 8D Problem Solving, Pharma industries’ USFDA recommended 7 step approach and Six Sigma’s DMAIC approach.

Training Contents

Overview

- Overview of Problem-solving

- Need for Problem-Solving

- Managing a Problem Vs Problem Solving

- Definitions – Correction, Corrective Action & Preventive Action

Step by Step Approach to Problem-Solving

1. Identification

- Discover

- Define

- Use of 5W2H questions

- Document

2. Containment Action

- Assessing the problem and its risk

- Forming Effective Teams

- CFT & CHT

- Damage control – Interim Actions

- Communication plan

3. Investigation

- Planning

- Data / Evidence Collection

- Conclusion

4. Cause Analysis

- Brainstorming for Problem-solving

- Fishbone Analysis

- FMEA

- Is – Is Not Analysis

- Process Mapping

- Data and Statistical Analysis

- Data collection

- Graphical Tools

- Why-Why Analysis

- Validation of Root causes

- Statistical Analysis

- Evidence

5. Improvement

- Permanent Corrective Action

- Solution Generation

- Pilot Implementation

- Solution Action Plan

- Preventing Recurrence

- Control Plan

- SPC

- Poka Yoke

6. Closure

- Verification of Status

- Verification of Effectiveness

- HD

- Training & Documentation

- Closure

Training Duration

- Two days – 16 hours

About the Course

The Problem-Solving workshop caters to leaders and managers who are interested in solving the recurring problems and want to bring in the culture and team-based approach of systematic problem solving to every level of people in the organisation. We deal with the most relevant tools in the step-by-step approach. We can take up the actual cases of recurring problems in the company as an example and study for the workshop. The course covers essential problem-solving tools like problem definition, containment action, root cause analysis with QC tools, root cause validation using statistical tools, corrective action, preventive action, escape points, Poka-yoke and more.

Course Objectives

At the end of the course, participants will be able to understand and appreciate

- Cost of Poor Quality

- The need for Systematic problem-solving

- Various approaches to problem-solving

- Difference between correction, corrective action and preventive action

- Team approach enhance effective solutions and learning

- Risk assessment and containment actions

- Root cause analysis

- Statistical tools

- Arriving at an effective action plan

- Preventing the defects

Target Audience

- Managers responsible for process improvements

- Quality Managers, Internal and External Auditors

- Shop floor managers and supervisors

- Production and Maintenance Managers

- Product Design Engineers

- Research Engineers & Scientists

Workshop Methodology

CSense Workshop approach is based on scientifically proven methodologies of Learning, which includes Learning by

- Listening – Classroom sessions & Audio-Visuals

- by Teaching

- Doing

- Examples & Exercises at the end of each step

- Application

- We will provide the required Templates and formats for each tool

- During the course, we will form 3 to 4 cross-functional teams

- We will help each team choose a specific problem (either an open Non-conformance or a recently closed out non-conformance)

- We encourage the teams to choose different types of problems like Audit observations, internal failures/rejections, customer complaints, machine breakdown or accidents.

- Then we will guide the participants to work on their assigned problem with the new approach – application & documentation.

- Faculty will help the teams to apply the learning on the problems and explain the practical doubts.

- After each step, teams will present their work.

Batch Size

Min 12 and Max 20 Participants per batch

Customisation

We can customise the deliverable as per client’s requirements.

Certification

- Certification Criteria: 90% attendance in Training Sessions, participation in activities and 70% Score in written test

- The test will be conducted on 2nd day of training

- Laptop/desktop with provision to install software packages for participants to be arranged by the client.

AdditionalSupport

Continued coaching and hand-holding support could be provided by CSense after the workshop for successful project completion, as an optional engagement.