Lean Six Sigma can be implemented anywhere, wherever there is a business process and a problem.

We use the methodology in engineering companies from a simple rack manufacturing company to a complex rocket engine manufacturing company; retail showrooms to back-office processes, computer manufacturers, food manufacturers, construction companies, banks and hospitals.

I am sharing some sample project and the benefits we achieved by implementing Lean Six Sigma methodology in various Non-Manufacturing, Non-Engineering, Service Industries. Also listing down some Lean Six Sigma Case studies in Service industries.

Lean Six Sigma in Retail Industry

- Increase walk-ins by

- Changing customer perceptions (pricing and delays)

- Improving Pricing policies

- Reducing waiting time (quick response to RfQs, enquiries, small order purchases and billing)

- Market samples analysis

- Changing customer perceptions (pricing and delays)

- Improving floor space utilisation

- ‘Sales per Sq.ft’ improvement

- ‘Sales per staff’ improvement

- Improving the impact of Visual Merchandise

- Experimental Validation

- Sales per Sq.ft display metric improvement

- Display value per Sq.ft metric improvement

- Reducing Cost of Operations by

- Reducing shrinkages

- System shrinkages

- Operational shrinkages

- Cost per employee/cost per sq. ft area

- Improving Inventory turns

- Order – GRN excess reduction

- Order/supplier / purchase team-wise aging improvements

- Reducing inventories

- Right-sizing warehouse inventory based on Lean Scheduling

- Vendor assessment and customised cyclic ordering

- Reducing request to receipt lead-time for stores (from the warehouse)

- Optimising purchase process

- Optimising RoLs (Reorder levels)

- Reducing shrinkages

- Improving the shopping experience

- Customer-Centric Processes from entry to exit

- Customer-focused facilities – Parking, refreshments, escorting, etc

- Improving ambience of the outlet

- Reducing waiting time in billing and packing/delivery counters

- Customer feedback rating

- Customer grievances and complaints

- Customer-Centric Processes from entry to exit

- Improve conversion ratio

- Reduce ‘no-bill’s by avoiding/minimising stock-outs

- Enhancing employee involvement

- Happier employee programs

- Improving employee loyalty

- Reducing infant attrition

- Improving competency score/competency match across the company

- Defining metrics based on KRAs and KPIs

- Customer satisfaction rating

- Customer feedback rating

- Customer grievances and complaints

- Happier employee programs

Some More Cases of Lean Six Sigma in Retail Industry

- Reducing System Faults

- Determining the sales impact of markdown reductions

- Determining the sales impact of bundling products with accessories

- Streamlining the hiring process

- Mitigate consumer frustration and reduce cost

- Streamline the item-order cycle

- Reconfigure the loading dock layout, Eliminate extra handling of merchandise

- Freight moving from suppliers to distribution centres

- Reduce cycle time in getting merchandise into the buildings

- Better handle client account queries and questions over the phone

- Attribute control in order to find out if an item is either good or defective

- Identifying factors influencing recycle rates

- Lowering lead times

- Supply chain improvements

Lean Six Sigma Case Studies in HR Function

- A company has reduced its recruiting cycle time by 56% by

- simplifying the job application and better defining the sales representative position.

- use of simple technology to streamline some processes

- by improving the company’s social media presence and

- Identifying and utilising the most effective talent source for their company.

- Another company reduced the TAT of the recruitment process by more than 66% by

- considering the candidates as Customers and defining VALUE from their perspectives

- eliminating/reducing waiting time – waiting for feedback, indecisions on hold prospects, waiting for offer releases and waiting on application information releases

- end-to-end process streamlining and re-engineering the recruitment process.

Some more Cases of Lean Six Sigma in HR Function

- Reducing delays in Truck TAT (Material handling, major focus area Main Gate Entry and Exit Process)

- Improving on-time arrival of people in the office

- Improving / Achieving Competency score of the organisation

- On-time and complete issuance of uniforms & PPE kits to plant staff

- Improving the robustness of performance management system

- Reducing safety incident (near-miss and accidents) in the factory and improving the robustness of corrective actions to avoid recurrence of such events

- On-time settlement of PF benefit for the retiring staff

- Improving timely completion, 100% coverage of recruit Induction process

- Improving reliability and on-time redressal of employee grievances

- Improving adherence to legal and statutory compliances

- Improving employee satisfaction towards appraisal process

- Improving on-time availability of agents in telecom

- Reducing infant attrition rate in sales and operations department

Lean Six Sigma in Finance & Insurance

- Process Risk assessment and mitigation in a global bank

- Avoidance of wrong entries in ERP system in a global bank

- Improving On-time payment to suppliers in a Retail company

- Achieve 100% Statutory Compliance in a service company

- Reducing collection TAT and reduce the risk associated with the collection process in an NBFC

- Reducing TAT of client on-boarding in an NBFC

- Reducing claim settlement TAT across verticals in a major insurance company (Life, Fire, Motor, Marine, Medical)

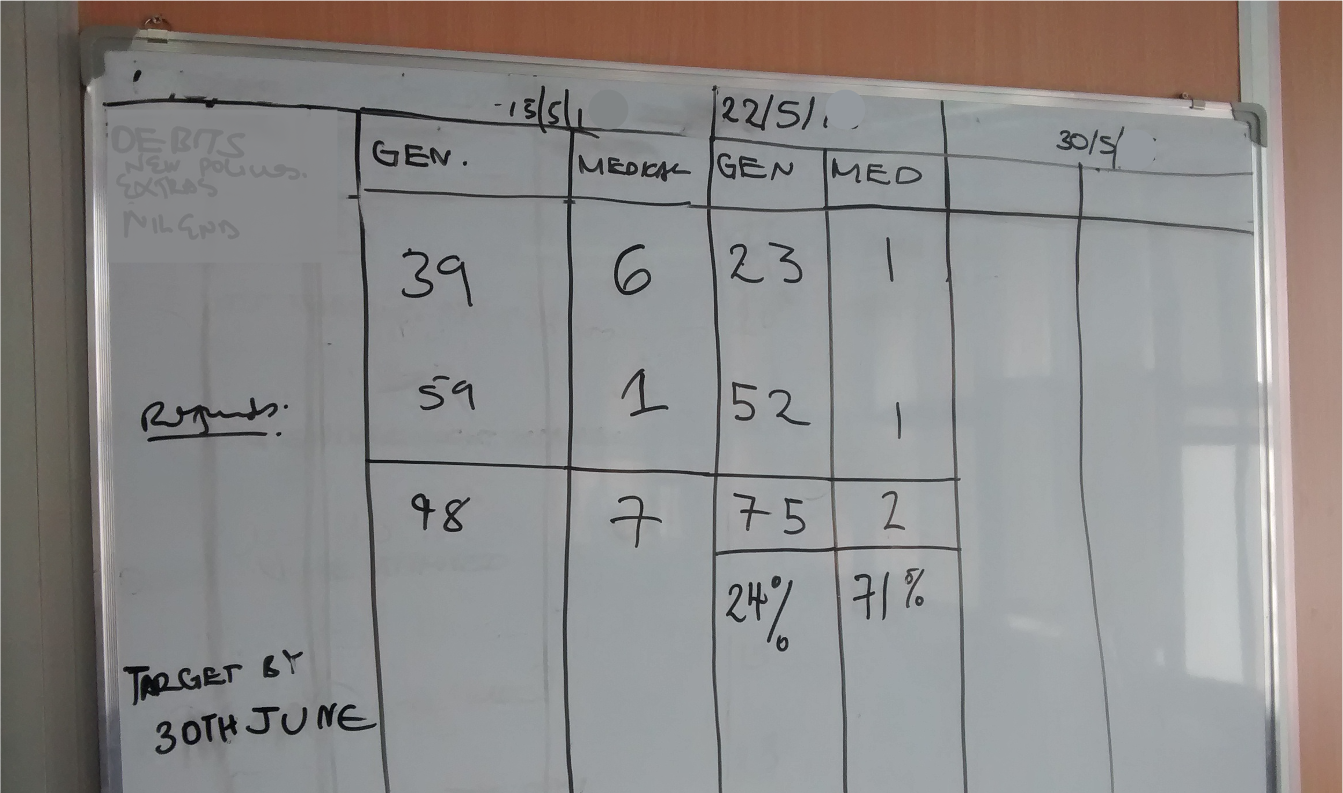

- Improving on-time issuance of policies