What is Statistical Process Control?

SPC, or statistical process control, is a framework embedded with the statistical tools used to monitor, control, and improve processes.

Conceptually, it applies the statistical technique to control the processes to improve their reliability and predictability.

What is data?

Data is a collection of facts, such as numbers, words, measurements, observations or even just descriptions of things.

Any and every piece and form of information.

What is Data Analysis?

The collection of structured data – preferably of samples – arranging and visualising data, fitting a statistical model to the data and inferring or predicting the population’s behaviour or the future.

Data Analysis helps in solving business problems using limited structured data and statistics. Data analysis could be done using simple spreadsheets like MS – Excel or analysis software like Minitab, JMP, etc.

Principles of SPC

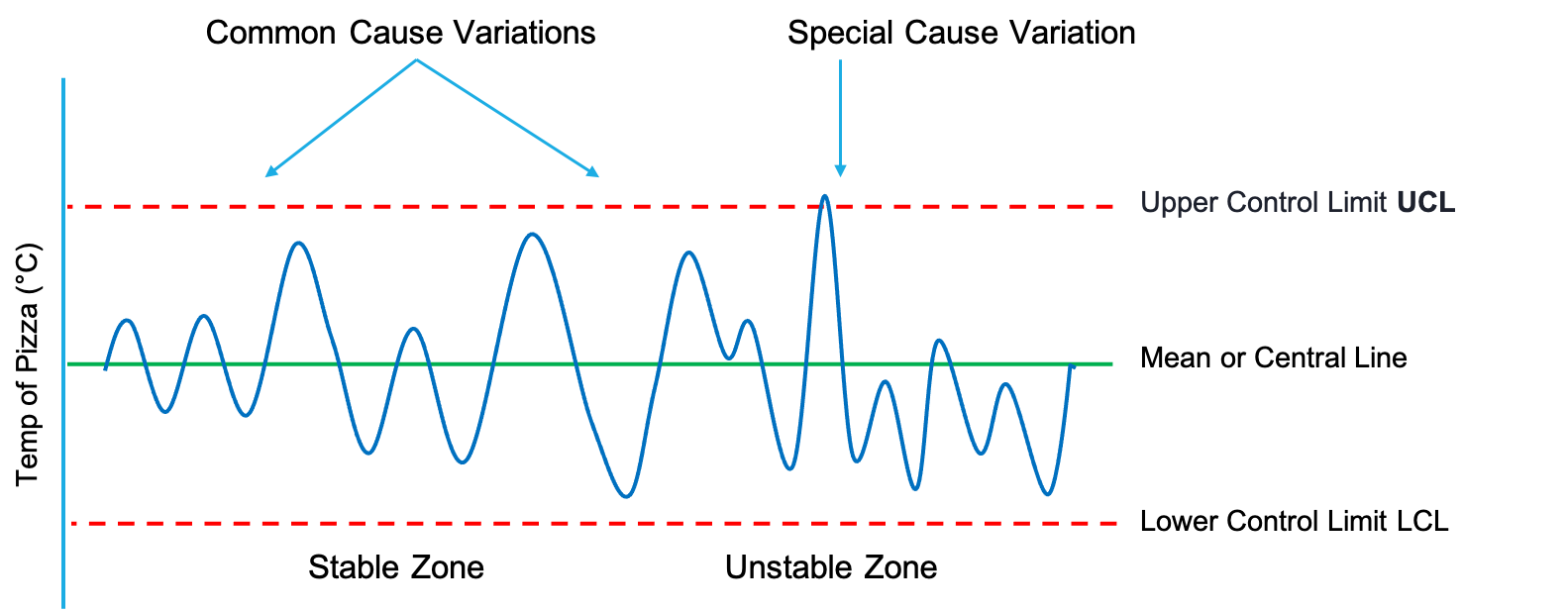

1. Every process has variations

2. Operators were reacting to every variation from the target measurement by adjusting the process (say machine setting).

3. Those adjustments cause more deterioration – making processes worse instead of improving them.

4. Continuous measurement of such parameters will help operators to understand the process variations.

5. Once the process owners understand its inherent variations, they can decide when to adjust a process and leave it untouched.

Course Objectives

- Understanding the basics of Statistics

- Central tendency

- Dispersion of data

- Populations and Samples

- Descriptive and Inferential Statistics

- Understanding the Measurement System, Variations in Measurement Systems and analysing it

- Interpreting data to understand the voice of the process

- Understanding the differences between common cause and special cause variation

- Analysing process variation

- Understanding the characteristics of a normal distribution and how to use a normal curve in estimating the proportion of product that meets specifications

- Concluding using data

- Getting to know how control charts and histograms aid in assessing process capability and how to use sample data in estimating population characteristics

- Understanding the need and method of calculating the capability of processes

- Utilising SPC

- Types of control charts

- How to monitor processes using control charts

- Use of variable control charts

Course Structure

The 2 day workshop is designed in a way to cover the statistical tools used in different stages of SPC.

Perfectly balanced with the required amount of theory and statistics, the significance of analysis tools, hands-on with Minitab / excel with examples and exercises.

Course Contents

Day 1

- Intro to Statistics

- Basics of Statistics

- Types of DataProperties of data – central Tendency & Dispersion

- Understanding Statistics

- Descriptive Statistics

- Inference from Data

- Probability Distributions

- Inferential Statistics

- Measurement System Analysis

- Why MSA?

- Gage R&R

- Voice of Process

- Understanding the Behaviour of collected data

- Trends & Patterns in Data

- Trend Analysis

- Test for Normality

Minitab Tools

Descriptive Statistics, Gage R & R, Time Series Chart, Control Charts, Normality Test, Capability Analysis, Cp & Cpk, DPMO, Standard Normal Distribution (Z)

Day 2

- Data Analysis

- Basic Data Analysis Tools

- Histogram

- Pareto Analysis

- Box Plot

- Process Variation & Capability

- Variation & its consequences

- Variation – Stability Analysis

- Process Capability

- Control Charts

- Chart for Individual Values

- Chart for Variables (subgroup)

- Specific uses of other control charts

Minitab Tools

HistogramPareto ChartBox PlotI ChartI – MR Chart, X bar R Chart, N Chart, P Chart, NP Chart, U Chart

Note: The contents can be customised based on your requirements.

To whom will it be useful?

The basic SPC training program of 2 days (this workshop) is a comprehensive training for engineers, supervisors and middle-level managers aiming to clarify statistical concepts and know-how of statistical process control (SPC) tools and techniques.

Workshop Methodology

- CSense Workshop approach is based on scientifically proven methodologies of Learning, which includes

- Learning by Listening – Classroom sessions.

- Learning by Doing – Hands-on Support in applying the learning, pilot applications – with Minitab / Excel.