Are you calculating your process quality with this wrong Cpk Formula?

I came across a common mistake of using Long Term Sigma to calculate Cpk. Just wanted to elaborate and clarify. Click here to read the full article

I came across a common mistake of using Long Term Sigma to calculate Cpk. Just wanted to elaborate and clarify. Click here to read the full article

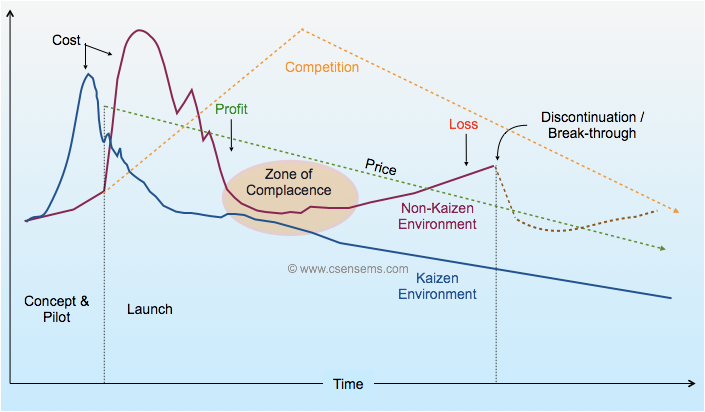

The Origin of Operational Excellence - Part 20 When we descend from the philosophy to action - we need some guiding principles. That's what I discussed in this article - The Principles of Kaizen! Click here to read the full article

The Origin of Operational Excellence - Part 21 What makes a Kaizen Workshop successful and thrilling? Sharing my thoughts and learning on Kaizen Workshops - the practice of Rapid Improvement. Click here to read the full article

The Origin of Operational Excellence: Part 22 Sharing my thoughts and experiences on the Practice of Kaizen Problem Solving, reasons for its high-impact results and how this approach is different from that of Six Sigma. Click here to read the full article

Origin of Operational Excellence: Part 23 In this final article on Kaizen, I discuss the need for suggestion systems in an organisation, how to improve the flow of valid suggestions and who is responsible for a successful suggestion system. Click here to read the full article

Muda Muda is a Japanese word meaning Waste. So, any activity that consumes time and effort and fails to produce the desired outcome is termed as Waste. In a production plant, people transport materials from one place to another for storage of for next processing. The activity of transporting consumes their time and effort. But the material does not get any value addition because of the mere transportation. Hence, transportation is termed as waste. Origin Muda is one of the fundamental...

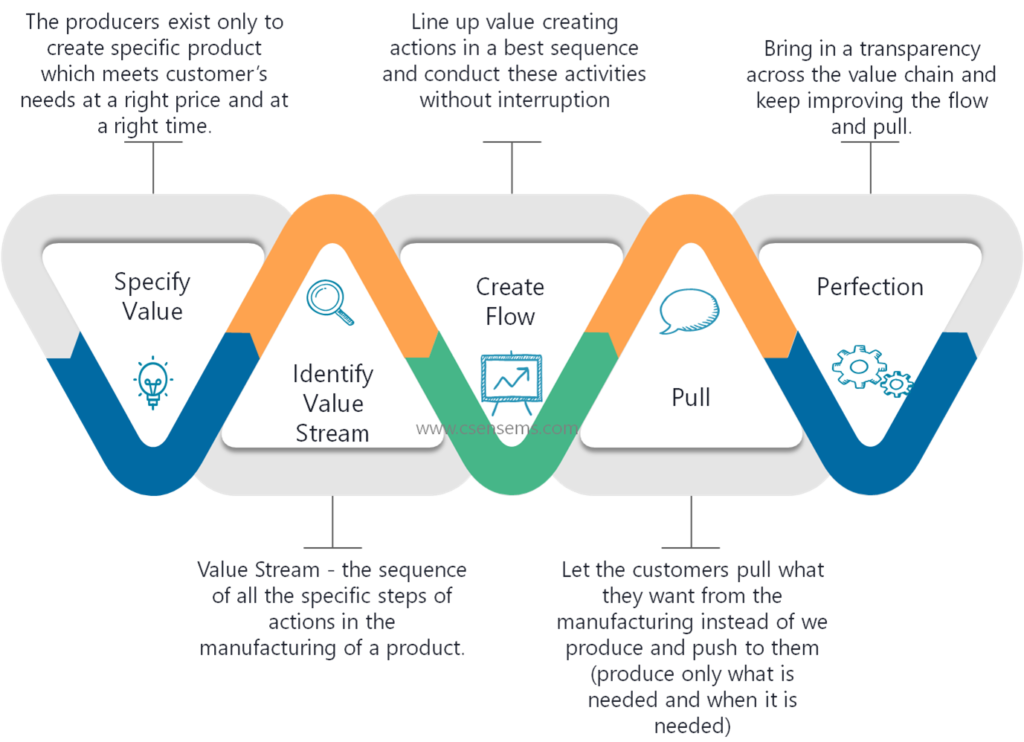

Lean Training with Value Stream Mapping (VSM) Lean Training with VSM is designed for people who are interested in learning the Lean Transformation using VSM. Value Stream Mapping – the mapping of Material and Information Flow – as it is known in Toyota is the fundamental tool of Lean Transformation. It helps us in mapping flow of information and material in a single process map. Lean is a strategic tool that has to be adapted and applied by the Top...