Are you calculating your process quality with this wrong Cpk Formula?

I came across a common mistake of using Long Term Sigma to calculate Cpk. Just wanted to elaborate and clarify. Click here to read the full article

I came across a common mistake of using Long Term Sigma to calculate Cpk. Just wanted to elaborate and clarify. Click here to read the full article

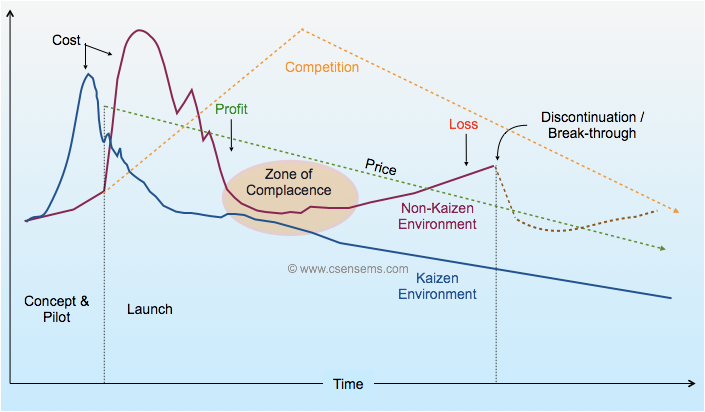

The Origin of Operational Excellence - Part 20 When we descend from the philosophy to action - we need some guiding principles. That's what I discussed in this article - The Principles of Kaizen! Click here to read the full article

The Origin of Operational Excellence - Part 21 What makes a Kaizen Workshop successful and thrilling? Sharing my thoughts and learning on Kaizen Workshops - the practice of Rapid Improvement. Click here to read the full article

The Origin of Operational Excellence: Part 22 Sharing my thoughts and experiences on the Practice of Kaizen Problem Solving, reasons for its high-impact results and how this approach is different from that of Six Sigma. Click here to read the full article

Origin of Operational Excellence: Part 23 In this final article on Kaizen, I discuss the need for suggestion systems in an organisation, how to improve the flow of valid suggestions and who is responsible for a successful suggestion system. Click here to read the full article

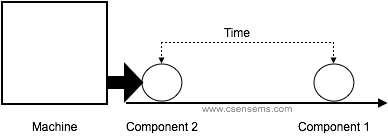

What is Cycle Time? Cycle Time is the time required by an operation or by a machine to complete the processing of one component. How to calculate Cycle Time? Start your stopwatch when a completed component comes out of a machine (or a person completes working on a component). Stop your timer when the next (consecutive) piece comes out of the machine (or a person completes working on the next component) Repeat this for 5 or more times and calculate...

Productivity Improvement through 5S 5S training & Workshop is designed to cater the needs of every level of staff in an organisation on keeping the workspace safe, pleasant and productive. It is not all about housekeeping and cleaning. But it is the simplest productivity improvement methodology. It can be successfully implemented by everyone, every day, everywhere - at every size of the organisation, whether it is a manufacturing, tool room, bank counter, restaurant, hospital, medical shop, IT company or be...

KAIZEN WORKSHOP Culture Building Engagement The Philosophy Kaizen – meaning change towards betterment, in essence, gradual improvement. The belief is that major improvements are possible through small and incremental changes. Unlike other improvement-events, these workshops are known for small and gradual changes leading to breakthrough results. The Culture Developing an organisational culture based on 3 principles, viz., Process Approach: What is happening (effect) is the outcome of processes (cause), System Thinking: Seeing the bigger picture and understanding everything as part of a...